Materials Science and Manufacturing Engineering Miscellaneous

- Two cutting tools with tool life equations given below are being compared:

Tool 1: VT0.1 = 150

Tool 2: VT0.3 = 300

where V is cutting speed in m/minute and T is tool life in minutes. The break even cutting speed beyond which Tool 2 will have a higher tool life is ________ m/minute.

-

View Hint View Answer Discuss in Forum

VT 0.1 = 150

VT 0.3 = 300

For break even cutting speed,

3ln150 – 3ln V – ln 300 – ln V

V = 106.66 m/ minCorrect Option: A

VT 0.1 = 150

VT 0.3 = 300

For break even cutting speed,

3ln150 – 3ln V – ln 300 – ln V

V = 106.66m/ min

- A firm uses a turning center, a milling center and a grinding machine to produce two parts. The table below provides the machining time required for each part and the maximum machining time available on each machine. The profit per unit on parts I and II are Rs. 40 and Rs. 100, respectively. The maximum profit per week of the firm is Rs. ________

-

View Hint View Answer Discuss in Forum

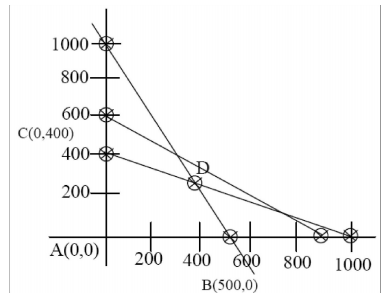

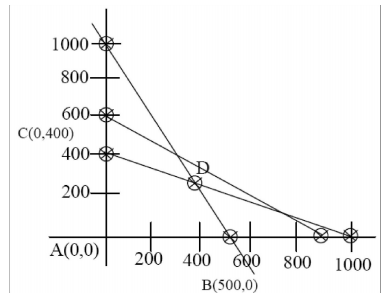

Zmax =40x + 100y

S.t 12x + 6y ≤ 6000, 4x + 10y ≤ 4000

2x + 3y ≤ 1800 x, y ≥ 0x + y ≤ 1 x + y ≤ 1 500 1000 1000 400 x + y ≤ 1 900 600

12x + 6y = 6000

4x + 10y = 4000

12x + 6y = 6000

12x + 30y = 12000- 24y = - 6000 y = 6000 = 250 24

4x + 10y = 4000

4x + 250 × 10 = 4000

4x = 1500x = 1500 = 375 4

Zmax =40x + 100y

= 40 × 375 + 100 × 250

= 15000 + 25000

ZD = 40,000/-

ZA = 0

ZB = 40 × 500 + 100 × 0

= 20,000

ZC = 40 × 0 + 100 × 400

= 40,000

Optional at (D) & (C).Correct Option: A

Zmax =40x + 100y

S.t 12x + 6y ≤ 6000, 4x + 10y ≤ 4000

2x + 3y ≤ 1800 x, y ≥ 0x + y ≤ 1 x + y ≤ 1 500 1000 1000 400 x + y ≤ 1 900 600

12x + 6y = 6000

4x + 10y = 4000

12x + 6y = 6000

12x + 30y = 12000- 24y = - 6000 y = 6000 = 250 24

4x + 10y = 4000

4x + 250 × 10 = 4000

4x = 1500x = 1500 = 375 4

Zmax =40x + 100y

= 40 × 375 + 100 × 250

= 15000 + 25000

ZD = 40,000/-

ZA = 0

ZB = 40 × 500 + 100 × 0

= 20,000

ZC = 40 × 0 + 100 × 400

= 40,000

Optional at (D) & (C).

- For an orthogonal cutting operation, tool material is HSS, rake angle is 22°, chip thickness is 0.8 mm, speed is 48 m/min and feed is 0.4 mm/rev. The shear plane angle (in degrees) is

-

View Hint View Answer Discuss in Forum

α = 22°

Chip thickness (t2) = 0.8 mm

feed = 0.4 mm/rev

speed = 48 m/mm

For orthogonal cutting feed= thickness of uncut chip (t1)r = t2 = 0.8 = 2 t1 0.4 tabθ = cosα = cos22 = 0.57 r - sinα 2 - sin22

θ = tan-1 (0.57)

θ = 29.7

Taper angle = tan-1 (0.27) = 15.10Correct Option: B

α = 22°

Chip thickness (t2) = 0.8 mm

feed = 0.4 mm/rev

speed = 48 m/mm

For orthogonal cutting feed= thickness of uncut chip (t1)r = t2 = 0.8 = 2 t1 0.4 tabθ = cosα = cos22 = 0.57 r - sinα 2 - sin22

θ = tan-1 (0.57)

θ = 29.7

Taper angle = tan-1 (0.27) = 15.10

- For a certain job, the cost of metal cutting is Rs. 180 C/V and the cost of tooling is Rs. 270 C/ (TV), where C is a constant, V is the cutting speed in m/min and T is the tool life in minutes. The Taylor's tool life equation is VT0.25 = 150. The cutting speed (in m/min) for the minimum total cost is________.

-

View Hint View Answer Discuss in Forum

Lm = 18C V Cg = 270C TV

VT0.25 = 150Vopt = V = C

n Lm

n 1 - n Cg

= 150

0.25 × 18 T

0.25 1 - 0.25 270 = 150

1 × 18 × 1504

0.25 3 270 V4 = 150(57.914) ×

T1

0.25 V4 V = 150 × 57.914 × 1 V

V2 =150 × 57.914

V =93.2 m/minCorrect Option: A

Lm = 18C V Cg = 270C TV

VT0.25 = 150Vopt = V = C

n Lm

n 1 - n Cg

= 150

0.25 × 18 T

0.25 1 - 0.25 270 = 150

1 × 18 × 1504

0.25 3 270 V4 = 150(57.914) ×

T1

0.25 V4 V = 150 × 57.914 × 1 V

V2 =150 × 57.914

V = 93.2 m/min

- The following data is applicable for a turning operation. The length of job is 900 mm, diameter of job is 200 mm, feed rate is 0.25 mm/rev and optimum cutting speed is 300 m/min. The machining time (in min) is_______.

-

View Hint View Answer Discuss in Forum

L = 900 mm

d = 200 mm

f = 0.25 mm/rev

v = 300 m/min

t =?

v = π DN m/minN = v = 300 = 478 rpm πD π × 0.2 t = L = 900 ≈ 7.539 min f.N 0.25 × 478 Correct Option: A

L = 900 mm

d = 200 mm

f = 0.25 mm/rev

v = 300 m/min

t =?

v = π DN m/minN = v = 300 = 478 rpm πD π × 0.2 t = L = 900 ≈ 7.539 min f.N 0.25 × 478