Materials Science and Manufacturing Engineering Miscellaneous

- The cutting length of the broach for the key way cutting in a 150 mm long east iron gear hub. Given that width of the key way is 9 mm depth of key way is 4.5 mm of finishing teeth = 4 and no. of semi finishing teeth = 8. Rise per tooth Pitch Roughing teeth 0.1 mm 22 mm Semi finishing 0.0125 mm 20 mm Finishing teeth 0 mm 20 mm

-

View Hint View Answer Discuss in Forum

NA

Correct Option: C

NA

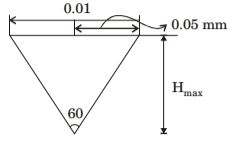

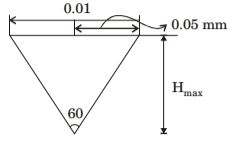

- A 60 deg symmetrical V tool is used in shaping at workpiece with a depth of cut of 0.1 mm and feed of 0.1 mm/stroke. The theoretical peak to valley height, in mm, of the surface produced is

-

View Hint View Answer Discuss in Forum

tan30° = 0.05 Hmax

Hmax = 86 microns = 0.086 mmCorrect Option: C

tan30° = 0.05 Hmax

Hmax = 86 microns = 0.086 mm

- The material most commonly used for manufacturing of machine tool beds is.

-

View Hint View Answer Discuss in Forum

Gray Cast Iron because of its damping nature and characteristic to absorb shock.

Correct Option: B

Gray Cast Iron because of its damping nature and characteristic to absorb shock.

- When the depth of cut in increased, the specific cutting energy

-

View Hint View Answer Discuss in Forum

Specific cutting energy = Fc W.t1

t ↑ SCE ↓ t1 → uncut chip thickness & depth of cut in orthogonal modelCorrect Option: B

Specific cutting energy = Fc W.t1

t ↑ SCE ↓ t1 → uncut chip thickness & depth of cut in orthogonal model

- In HSS tool materials the element tungsten can be completely replaced, without changing the material property by

-

View Hint View Answer Discuss in Forum

Molybdenum and Tungsten both increases hot hardness & abrasion Resistance.

Correct Option: A

Molybdenum and Tungsten both increases hot hardness & abrasion Resistance.