Materials Science and Manufacturing Engineering Miscellaneous

- A 600 mm x 30 mm flat surface of a plate is to be finish machined on a shaper. The plate has been fixed with the 600 mm side along the tool travel direction. If the tool over-travel at each end of the plate is 20 mm, average cutting speed is 8 m/min, feed rate is 0.3 mm/stroke and the ratio of return time to cutting time of the tool is 1: 2, the time required for machining will be

-

View Hint View Answer Discuss in Forum

Length travelled in forwarded stroke = 640 mm

Number of strokes = 100

Time for cutting = 8 min

Return time = 4 min

Total time =12 min.Correct Option: B

Length travelled in forwarded stroke = 640 mm

Number of strokes = 100

Time for cutting = 8 min

Return time = 4 min

Total time =12 min.

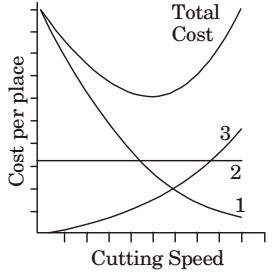

- The figure below shows a graph which qualitatively relates cutting speed and cost per piece produced.

The three curves 1,2 and 3 respectively represent

-

View Hint View Answer Discuss in Forum

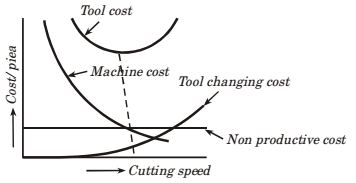

Machining cost = [Machining time × Direct Labour Cost]

So as cutting speed increases, machining time decreases and therefore machining cost decreases.Correct Option: A

Machining cost = [Machining time × Direct Labour Cost]

So as cutting speed increases, machining time decreases and therefore machining cost decreases.

- In a machining operation, doubling the cutting speed reduces the tool life to 1/8th of the original value. The exponent n in Taylor's tool life equation VTn = C. is

-

View Hint View Answer Discuss in Forum

Taylor’s tool life equation,

VTn = C ...(i)

Where, V = cutting speed and T = tool life

When cutting speed is doubled and tool life reduces to 1/8, then2V

1 T

n = C ...(ii) 8

Dividing equation (i) by equation (ii), we getVTn = 1 2V

T

n 8 or VTn = 2V

T

n = 2Vn2−3n 8

or 1 = 2⋅2−3n

or 1 = 2−3n + 1

or 2−3n + 1 = 20

or –3n + 1 = 0

or 3n = 1or n = 1 . 3 Correct Option: C

Taylor’s tool life equation,

VTn = C ...(i)

Where, V = cutting speed and T = tool life

When cutting speed is doubled and tool life reduces to 1/8, then2V

1 T

n = C ...(ii) 8

Dividing equation (i) by equation (ii), we getVTn = 1 2V

T

n 8 or VTn = 2V

T

n = 2Vn2−3n 8

or 1 = 2⋅2−3n

or 1 = 2−3n + 1

or 2−3n + 1 = 20

or –3n + 1 = 0

or 3n = 1or n = 1 . 3

- In an orthogonal cutting test on mild Steel, the following data were obtained

Cutting speed : 40 m/min

Depth of cut : 0.3 mm

Tool rake angle : +5º

Chip thickness : 1.5 mm

Cutting force : 900 N

Thrust force : 450 N

Using Merchants analysis, the friction angle during the machining will be

-

View Hint View Answer Discuss in Forum

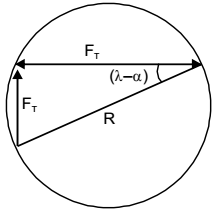

μ = F = FCsinα + FTcosα N FCcosα − FTsinα = 900sin5º + 450cos5º = 526.72 = 0.614 900cos5º −450sin5º 857.35

∴ λ = tan−1 = 31.5º

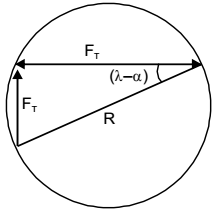

Alternative method

From Merchants' Circle

Given: FC = 900 N

FT = 450 N

Nowtan(λ − α) = FT = 450 FC 900 ∴ (λ − α) = tan−1

1

2

[where, α = Rake angle]

Friction angle, λ = 26.5 + 5 = 31.50Correct Option: B

μ = F = FCsinα + FTcosα N FCcosα − FTsinα = 900sin5º + 450cos5º = 526.72 = 0.614 900cos5º −450sin5º 857.35

∴ λ = tan−1 = 31.5º

Alternative method

From Merchants' Circle

Given: FC = 900 N

FT = 450 N

Nowtan(λ − α) = FT = 450 FC 900 ∴ (λ − α) = tan−1

1

2

[where, α = Rake angle]

Friction angle, λ = 26.5 + 5 = 31.50

- Through holes of 10 mm diameter are to be drilled in a steel plate of 20 mm thickness. Drill spindle speed is 300 rpm, feed 0.2 mm/rev and drill point angle is 120°. Assuming drill over travel of 2 mm, the time for producing a hole will be

-

View Hint View Answer Discuss in Forum

Given: Diameter of hole,

d =10 mm

Thickness of steel plate,

t = 20 mmα = 120 = 60º 2

Break through distance,A = d = 10 = 2.8867 mm 2tanα 2tan60º

Total length of tool travel,

l = t + A + 2

= 20 + 2.8867 + 2 = 24.88

Time for drilling= l = 24.88 = 0.4147 min fN 0.2 × 300

= 24.88 sec ≈ 25 sec.Correct Option: B

Given: Diameter of hole,

d =10 mm

Thickness of steel plate,

t = 20 mmα = 120 = 60º 2

Break through distance,A = d = 10 = 2.8867 mm 2tanα 2tan60º

Total length of tool travel,

l = t + A + 2

= 20 + 2.8867 + 2 = 24.88

Time for drilling= l = 24.88 = 0.4147 min fN 0.2 × 300

= 24.88 sec ≈ 25 sec.