Materials Science and Manufacturing Engineering Miscellaneous

- Consider the following statements: During the third stage of tool wear, rapid deterioration of tool edge takes place because

1. Flank wear is only marginal

2. Flank wear is large

3. Temperature of the tool increases gradually

4. Temperature of the tool increases drastically

Which of the statements given above are correct?

-

View Hint View Answer Discuss in Forum

Correct Option: B

- In a machining operation chip thickness ratio is 0.3 and the back rake angle of the tool is 10°. What is the value of the shear strain?

-

View Hint View Answer Discuss in Forum

r = 0.3 = t1 , α = 10° t2 tanφ = rcosα 1 - rsinα tanφ = 0.3cos10° 1 - 0.3sin10°

φ = 17.3°

Shear strain = tan (φ – α) + cot φ

Shear strain = tan (17.3 – 10) + cot 17.3

Shear strain = 3.34Correct Option: D

r = 0.3 = t1 , α = 10° t2 tanφ = rcosα 1 - rsinα tanφ = 0.3cos10° 1 - 0.3sin10°

φ = 17.3°

Shear strain = tan (φ – α) + cot φ

Shear strain = tan (17.3 – 10) + cot 17.3

Shear strain = 3.34

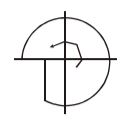

- A job of the shape shown in the figure below is to be machined on a lathe. The tool best suited for machining of this job must have

-

View Hint View Answer Discuss in Forum

Should be cut by negative SCEA.

Correct Option: A

Should be cut by negative SCEA.

- Orthogonal machining of a steel workpiece is done with a HSS tool of zero rake angle. The ratio of the cutting force and the thrust force on the tool is 1 : 0.372. The length of cut chip is 4.71 mm while the uncut chip length is 10 mm. What is the shear plane angle φ and friction angle β in degree?

Use Merchants theory

-

View Hint View Answer Discuss in Forum

α = 0 , Fc = 1 , Lc = 4.71 , Luc = 10 mm FT 0.372 LC = t1 = 4.71 = r LUC t2 10

r = 0.471 chip reduction coefficienttanβ = FT , where α = 0 FC

β = tan–1(0.372) = 2071°tanφ = rcosα 1 - rsinα tanφ = 0.471cos0 1 - 0.471sin0 Correct Option: B

α = 0 , Fc = 1 , Lc = 4.71 , Luc = 10 mm FT 0.372 LC = t1 = 4.71 = r LUC t2 10

r = 0.471 chip reduction coefficienttanβ = FT , where α = 0 FC

β = tan–1(0.372) = 2071°tanφ = rcosα 1 - rsinα tanφ = 0.471cos0 1 - 0.471sin0

- A single point cutting tool with a nose radius of 0.4 mm was used to turn a component in a lathe employing feed rate of 0.3 mm/rev. If the feed rate is doubled, the ideal surface roughness (peak-to-valley height) produced on the components will increase by a factor of

-

View Hint View Answer Discuss in Forum

Hmax1 = f2 8R Hmax2 = 2f2 = 4Hmax1 8R Correct Option: B

Hmax1 = f2 8R Hmax2 = 2f2 = 4Hmax1 8R