Materials Science and Manufacturing Engineering Miscellaneous

- Calculate the smallest punch diameter that can be designed for piercing sheet metal strip with the following data. Crushing strength of the punch material is 1500 MPa. Thickness of the sheet is 2 mm, factor of safety is 3, shear strength of the sheet material 500 MPa is

-

View Hint View Answer Discuss in Forum

Punching force = τ = πdt

= crushing strength [FOS = 3]Force = 1500 × π d2 3 4 1500 × π d2 = 500 × π × d × 2 3 4

d = 8 mmCorrect Option: C

Punching force = τ = πdt

= crushing strength [FOS = 3]Force = 1500 × π d2 3 4 1500 × π d2 = 500 × π × d × 2 3 4

d = 8 mm

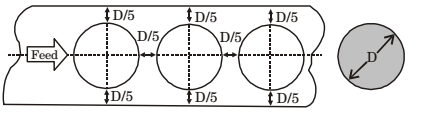

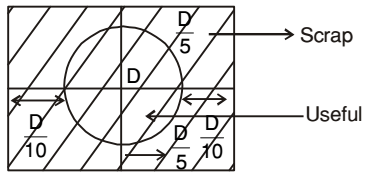

- The percentage scrap in a sheet metal blanking operation of a continuous strip of sheet metal as shown in the figure (correct to two decimal places) is _______.

-

View Hint View Answer Discuss in Forum

For blanking operation the piece obtained through hole is so, Scrap = hatched one area

% scrap =

scrap area

× 100 Total Area =

Total Area − hole area

× 100 Total Area =

1 − hole area

× 100 total Area

= 53.25%Correct Option: B

For blanking operation the piece obtained through hole is so, Scrap = hatched one area

% scrap =

scrap area

× 100 Total Area =

Total Area − hole area

× 100 Total Area =

1 − hole area

× 100 total Area

= 53.25%

- In a single point turning operation with cemented carbide tool and steel work piece, it is found that the Taylor's exponent is 0.25. If the cutting speed is reduced by 50% then the tool life changes by _______ times.

-

View Hint View Answer Discuss in Forum

V2 = 0.5V1,

V1 = V1 = 1 = 2 V2 0.5V1 0.5

V1Tn1 = V2Tn2T2 =

V1

n T1 V2 T2 =

V1

1/n =

V1

1/0.5 =

V1

4 T1 V2 V2 V2

= (2)4 = 16Correct Option: D

V2 = 0.5V1,

V1 = V1 = 1 = 2 V2 0.5V1 0.5

V1Tn1 = V2Tn2T2 =

V1

n T1 V2 T2 =

V1

1/n =

V1

1/0.5 =

V1

4 T1 V2 V2 V2

= (2)4 = 16

- In a sheet metal of 2 mm thickness a hole of 10 mm diameter needs to be punched. The yield strength in tension of the sheet material is 100 MPa and its ultimate shear strength is 80 MPa. The force required to punch the hole (in kN) is

-

View Hint View Answer Discuss in Forum

F = πdt Ts = π × 10 × 2 × 80 = 5026.5 N = 5.026 kN

Correct Option: A

F = πdt Ts = π × 10 × 2 × 80 = 5026.5 N = 5.026 kN

- Internal gears are manufactured by

-

View Hint View Answer Discuss in Forum

NA

Correct Option: B

NA